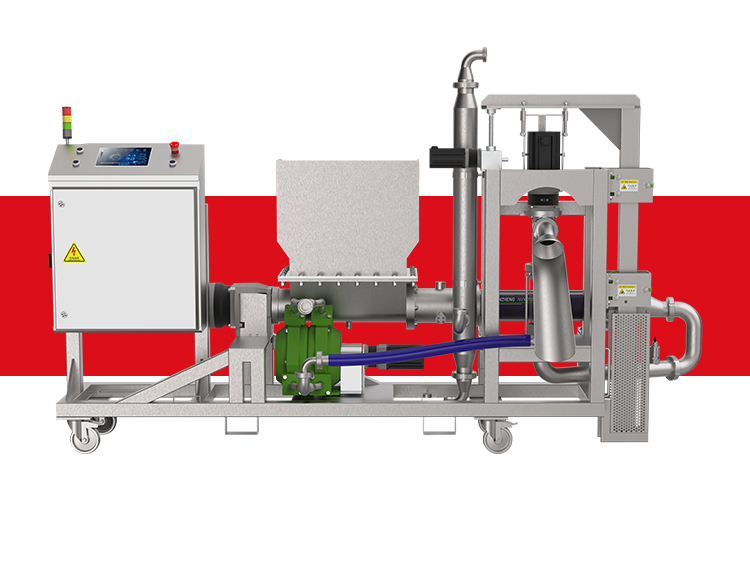

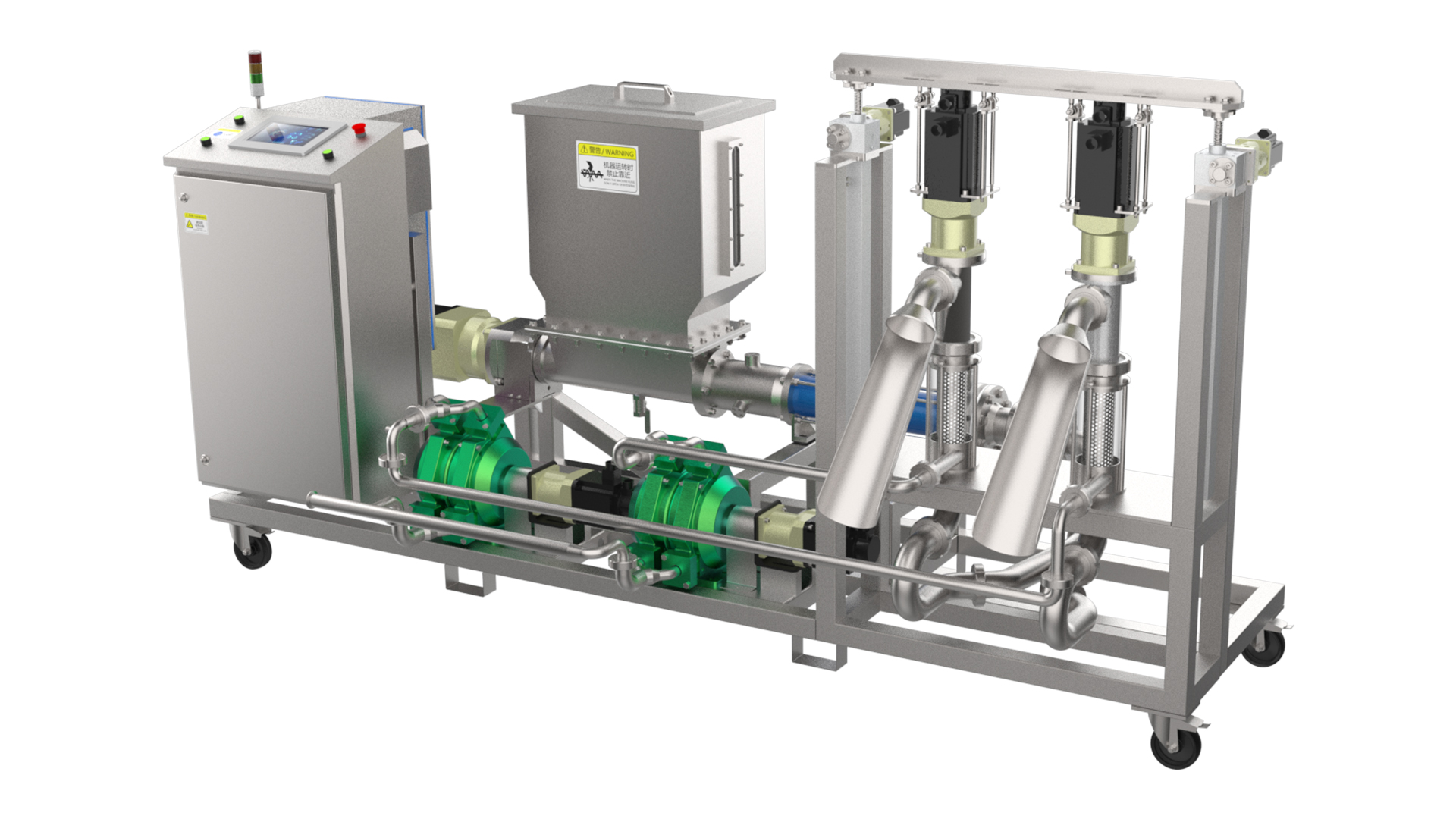

Vacuum fresh-locking juice extraction system NVX-3000

The Zhehan vacuum fresh-locking juicing system is a core processing equipment developed for the industrial mass production scenario of fruit and vegetable juices. The equipment takes "full vacuum oxygen isolation + flexible precise pressing" as its core technology. From raw material crushing to juice output, the entire process is isolated from oxygen, effectively solving the pain points such as juice oxidation and Browning, nutrient loss, and flavor damage in traditional juicing processes. At the same time, it takes into account high production efficiency, compliance, and multi-category adaptability. It provides core support for the production of high-quality products such as HPP juice, freshly squeezed fruit and vegetable juice, and compound fruit and vegetable beverages.

I. Core Working Principle

The equipment adopts an integrated design of "pre-vacuum chamber + dynamic pressing + vacuum conveying". The vacuum degree in the juicing chamber and conveying pipeline is stably controlled at -0.07 to -0.09MPa through a central vacuum unit. After pretreatment, the raw materials enter a closed vacuum chamber, where flexible crushing and gradient pressing are completed in an oxygen-free environment. The juice is directly conveyed to the subsequent temporary storage or clarification stage under negative pressure, avoiding contact with air throughout the process. This process can effectively inhibit the activity of polyphenol oxidase, reduce the oxidation rate of fruit juice by over 80%, retain heat-sensitive nutrients such as vitamin C and anthocyanins as well as the original flavor of fruits and vegetables, and ensure the bright color and pure taste of fruit juice from the source.

Ii. Core Configuration and Technical Parameters

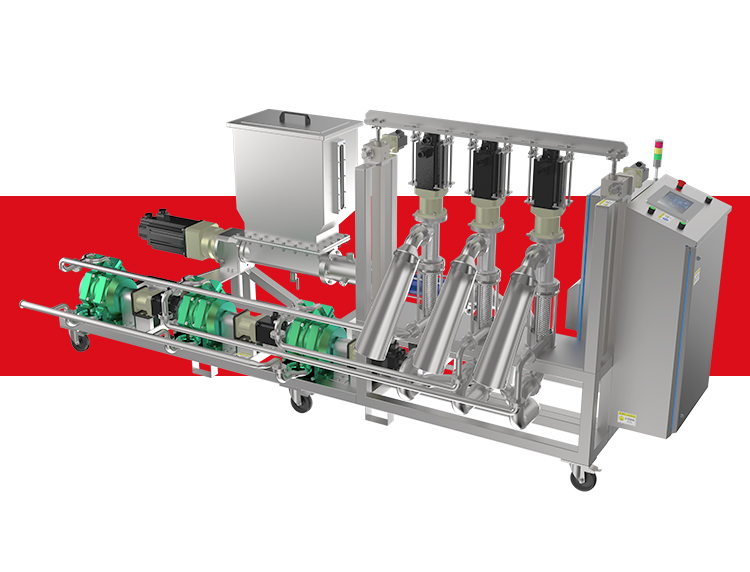

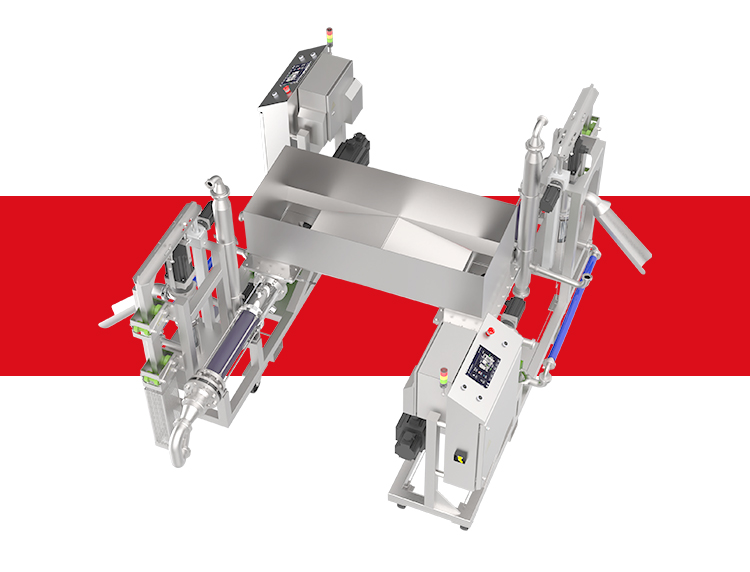

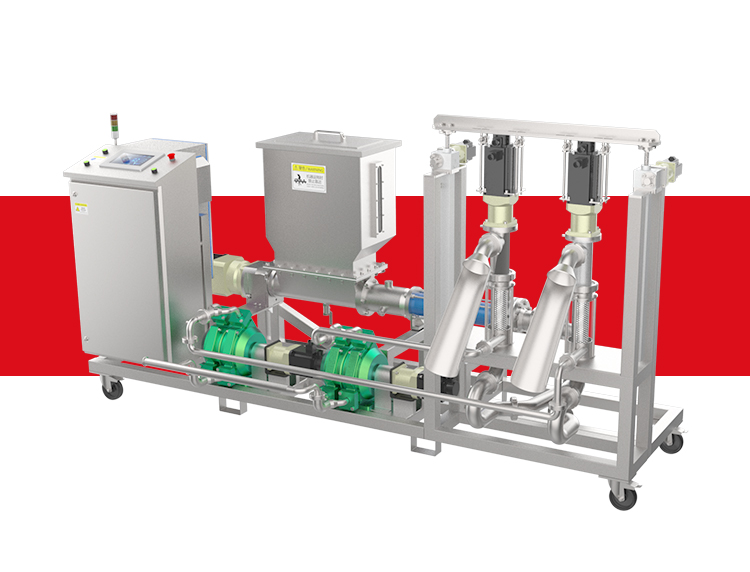

The equipment adopts a modular design, and all core components comply with food industrial-grade standards, meeting the demands of beverage factories with different production capacity scales.

Vacuum system: Equipped with an industrial-grade central vacuum unit, supporting dynamic adjustment of vacuum degree, and equipped with pressure sensors and automatic pressure replenishment devices to ensure a stable negative pressure environment. The pipeline is made of 316L stainless steel, with an inner wall electrolytically polished (roughness Ra≤0.4μm), reducing the risk of residue and microbial growth.

Pressing system: It adopts a two-stage structure of variable frequency screw pressing and hydraulic secondary pressing. The screw speed and pressing pressure can be precisely controlled (0.3-0.8MPa). Equipped with customized grading screens, the pore size can be adjusted according to the clarity requirements of the juice (0.1-0.5mm), with a juice yield as high as 82%-85%, which is 5%-8% higher than that of traditional equipment.

Control system: Equipped with a PLC intelligent control system and touch screen operation terminal, it supports real-time collection and visual monitoring of over 120 process parameters. It is equipped with a built-in storage function for over 50 product formulas, allowing for quick switching of processing parameters for different fruit and vegetable categories, with the production change time reduced to within 30 minutes. It is equipped with a multi-level early warning mechanism. When parameters are abnormal, it will automatically alarm and link the equipment for adjustment to ensure production stability.

Auxiliary system: Integrated CIP in-situ cleaning interface, supporting 360° cleaning without blind spots; Equipped with an inert gas (nitrogen) displacement device, the juice temporary storage stage can maintain a slightly positive pressure nitrogen environment, further enhancing the freshness retention effect. An optional raw material pretreatment linkage module can be equipped to achieve seamless integration with grading, sorting, cleaning and water draining equipment.

| Project | Parameter | Remarks |

| Overall dimensions | Approximately 3.3 meters in length, 1.5 meters in width and 1.7 meters in height | |

| Production capacity | 2.5-3.5 tons per hour | Different materials result in different production capacities |

| Control system | Siemens PLC | |

| Feeding system | 7.5 kw | Servo control |

| Vacuum juicing | 6Kw | Servo control |

| Conveying system | 3.6kw | Servo control |

Iii. Core Product Advantages

Lock in freshness and protect the product, quality upgrade: The entire vacuum oxygen isolation process ensures that the residual oxygen rate of the juice is ≤0.5%, and the retention rate of vitamin C is over 90%. The juice is bright in color and free from oxidation and Browning. It can extend the shelf life of the product without adding preservatives, meeting the production needs of high-end NFC juice and other high-quality products.

High yield and efficiency, with controllable costs: The double-stage pressing design significantly increases the juice yield and reduces raw material loss. Variable frequency motors are suitable for different load conditions, and their energy consumption is reduced by 15% to 20% compared with traditional equipment. The automated control system reduces manual intervention, increasing the per capita operational efficiency by more than eight times.

Multi-product adaptation and flexible production: It can precisely adapt to the processing of over 30 kinds of raw materials, including berries (grapes, blueberries, strawberries), pectin fruits (apples, pears), stone fruits (pitted citrus fruits, mangoes), vegetables (spinach, carrots), etc. By adjusting the pressing parameters and screen specifications, a full-category production switch from clear juice to juice with pulp can be achieved.

Iv. Applicable Scenarios

The equipment is widely applicable to various large-scale beverage production enterprises, especially suitable for:

HPP juice production line: such as freshly squeezed orange juice, apple juice, strawberry juice and other additive-free juice production;

Compound fruit and vegetable beverage factory: For precise juicing and flavor fusion of various fruit and vegetable raw materials;

Functional beverage enterprises: Production of high-end beverages that need to retain specific nutrients (such as antioxidants and vitamins);

Fruit and vegetable deep processing factory: Providing pre-juicing processing for products such as fruit puree, jam, and concentrated fruit juice.

V. Customized Services and After-sales Assurance

According to the production capacity scale, raw material characteristics and product positioning of different beverage factories, customized solutions can be provided: including capacity expansion, process module upgrading (such as low-temperature crushing, aseptic conveying), seamless integration with existing production lines, etc. At the same time, we provide full life-cycle services, covering equipment installation and commissioning, operator training, remote operation and maintenance support, regular inspection of core components, etc., to ensure the long-term stable operation of the equipment.