- Home

- About Us

-

Product Center

- Stainless steel filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

- Stainless steel straight-through filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- News Center

- Contact us

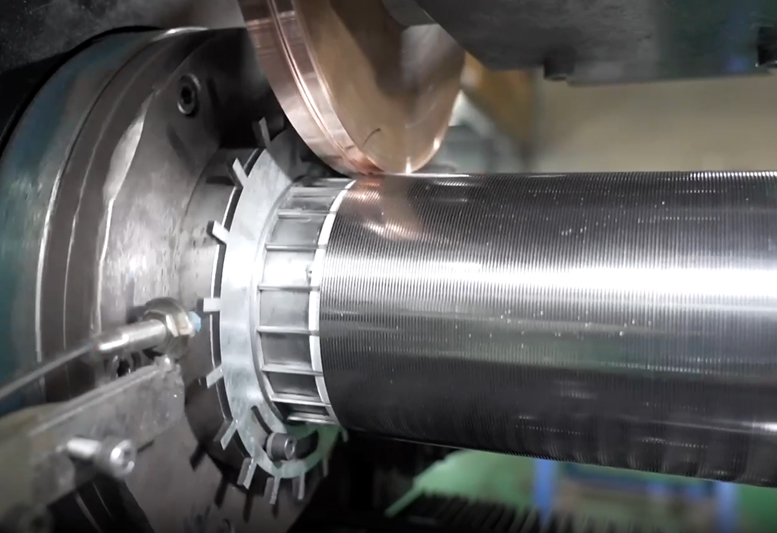

At present, most Johnson networks use trapezoidal wires. There are many benefits of using trapezoidal wires:

At present, most Johnson networks use trapezoidal wires. There are many benefits of using trapezoidal wires:

The continuous gaps greatly increase the water passage area, thus ensuring good contact with the aquifer.

2. The V-shaped cross-section structure prevents blockage and ensures smooth flow.

3. Continuous pores can be used for a long time.

4. The trapezoidal filter pipe has a solid structure, high porosity and precise gap dimensions.

5. The trapezoidal wire filter pipe is easy to backwash, has a long service life and a low comprehensive cost. The screen plate plays a very good filtering and dewatering role in solid-liquid separation and solid-solid separation. Johnson Network is mainly used for sewage treatment, laundry water purification, and wastewater treatment in the poultry, fishery, and fruit and vegetable industries.

The welding process and reasonable support structure ensure that when installed on the high-frequency Johnson screen, it will not cause situations such as broken bars or wires due to the fatigue deformation and de-welding of the metal, which leads to the separation of the screen from the flat iron. The raw materials of stainless steel Johnson mesh are all made of stainless steel wire (202T), which has high strength and corrosion resistance. The reversible Johnson mesh is mainly used to chamfer the screen wire during the production process of the screen. When one side is severely worn during use, it can be manually or mechanically flipped, which can extend the service life of the screen by more than 30 years.