- Home

- About Us

-

Product Center

- Stainless steel filter element

-

Medium and small-sized filters

- Stainless steel Angle filter

- Stainless steel straight-through filter

- Stainless steel pre-filter

- Stainless steel Y-type filter

- Stainless steel Y-type variable-angle filter

- Stainless steel respirator

- Stainless steel single-core filter

- Stainless steel single-bag filter

- Stainless steel magnetic filter

- Stainless steel gas filter

- Online filter (external scraper)

- Large filter

- News Center

- Contact us

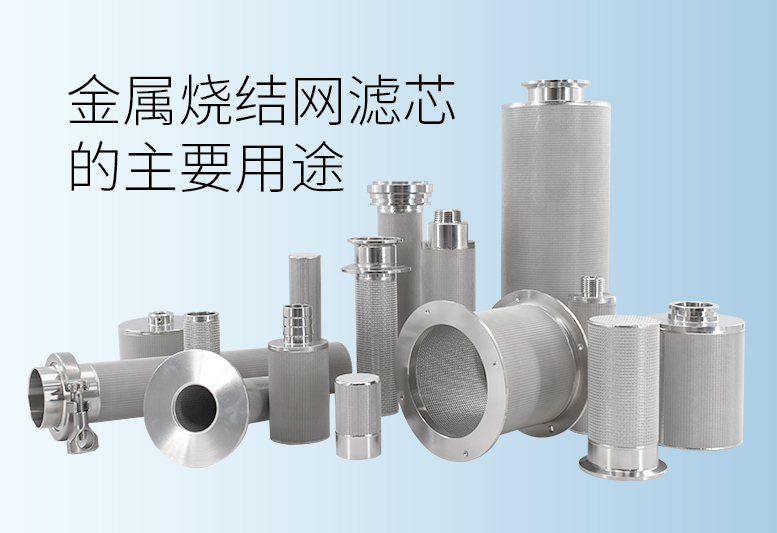

The main uses of metal sintered mesh filter elements:

The main uses of metal sintered mesh filter elements:

1) It is used as a dispersed cooling material in high-temperature environments.

2) For gas distribution and liquid bed orifice plate materials.

3) It is used for high-precision, high-reliability and high-temperature filtration of materials.

4) Sintered mesh filter elements are used in high-pressure backwash oil filters.

Metal sintered mesh filter elements are used for high-pressure medium filtration. Separation of oil sands in oil fields Machinery, ships, fuel, lubricating oil, hydraulic starting oil; For complete sets of chemical equipment in the chemical industry

Process filtration High-temperature gas dust removal Food filtration Medical filtration Water treatment.

Metal powder sintered filter elements have the following excellent properties:

Metal powder sintered filter elements have excellent filtration performance (0.5 to 200μm).

2: Stable shape, with components having high strength;

3: High-temperature resistance (can operate in an environment as high as 900℃);

4: Strong corrosion resistance;

5: It is shock-resistant and can withstand high alternating loads.

6: Excellent air permeability and separation;

7: Good backwashing, easy regeneration of components, etc.

Metal powder sintered filter elements, with their outstanding product performance, are widely used in industries such as petrochemicals, chemistry, fine chemicals, coal chemicals, food and beverage, nuclear power, shipbuilding, and automotive manufacturing.

It is particularly suitable for the following application scenarios:

1: Catalyst filtration

2: Filter liquids and gases;

3: Mother liquor recovery and filtration in PTA production;

4: Filtration in food and beverages

5: Boiling vaporization bed

6: Liquid tank flushing bubbles;

7: Fireproof and explosion-proof;

8: Balance and dampen the airflow

9: Probe protection of the sensor

10: Filtration and noise reduction on pneumatic equipment;

11: Fly ash treatment

12: Gas homogenization and pneumatic conveying in the powder industry, etc.